By: Derek Perkins

What are cannabis concentrates and how are they made?

With emerging technologies in the growth and extraction of marijuana, consumers can obtain a variety of products for consumption. It is often difficult for consumers to understand what products are, let alone why they should consume them. The purpose of this article is to demystify the world of concentrates. We will discuss the importance of starting material, how products are extracted, and why consumers should smoke consciously to maximize health benefits. The goal is to increase comfortability with concentrates, allowing the use of a more diverse range of products that could increase neurological and metabolic health.

How are different Cannabis Concentrates made?

The first step in differentiating types of concentrates is understanding the starting material’s genetics and exposure to cannabinoids and terpenes. O’driscoll (2022) explains in her article: A Guide to Drying and Curing Cannabis, that two approaches are:

- Immediately freeze-drying the flower upon harvest to use for “Live” concentrates/very sensitive procedures

- The normal 10-day dry and 2-8 week curing time. The dried and cured flower goes through degradation and oxidation of terpenes and cannabinoids through exposure to natural air, light, and the various temperatures involved in the process

The freeze-dried samples have their cannabinoids and terpenes preserved at maximum freshness by sealing, vacuuming, and freezing flower samples before the extraction process takes place while the plant is considered “alive”. Both procedures produce material for concentrates, however, the colder the temperature the product stays throughout the process, the more terpenes and cannabinoids are preserved. This allows for a final product that is high in purity and considered to be as close to the plant’s natural taste and effects as possible.

What is the difference between FECO and RSO?

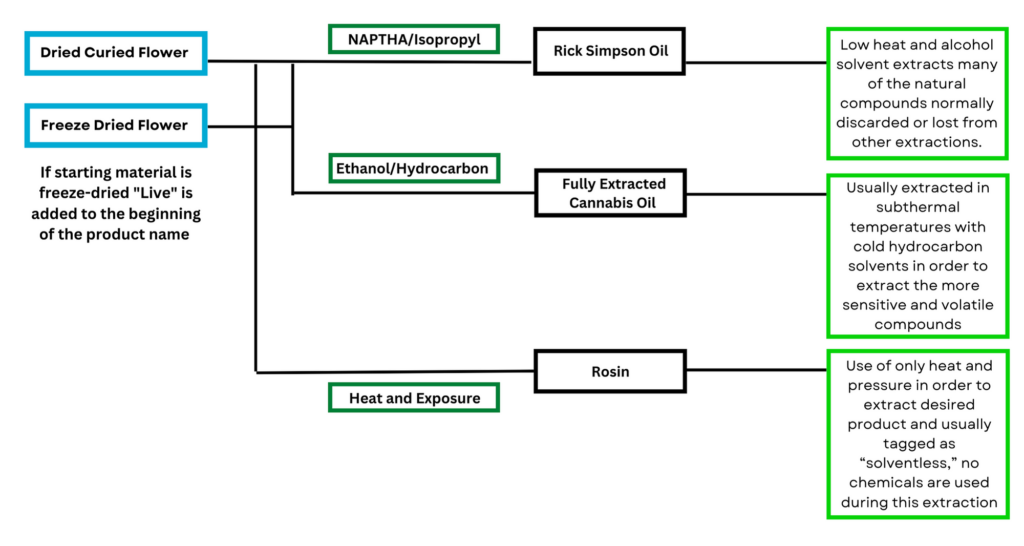

The distinction is between Rosin, Rick Simpson Oil (RSO), and Fully Extracted Cannabis Oil (FECO). The most notable difference between these methods is the parameters under which these extractions were executed as well as the solvents utilized. The temperature of the product is vital for terpene extraction, so anything using heat or distillation does not typically yield high terpene concentrations. Figure 4.20 shows a brief diagram depicting the relationship between the starting material and the extraction methods. Often, manufacturers use cold-temperature extraction methods to gather high-purity extracts that are either oils or powders to use as a starting material.

How is Solventless Rosin made?

In its simplest form, Rosin is “solventless extraction”. According to Ben McCabe, President of Rosin Tech Labs, the extraction process for rosin begins with the quality of the starting material (2020). The next step involves washing the flower buds in an ice bath and collecting the cannabinoids and terpenes by agitating the entire solution. By doing this, unwanted plant materials will be removed. The result is a green crystallized residue called kief, which is then pressed into hashish bricks or sold. Hash bricks are then wrapped in parchment-like paper to collect the oil produced after they are heated and pressed under extreme pressure. The final product is called Rosin or solventless extraction. The composition, texture, and concentration of the final cannabinoid/terpene product are altered by varying the starting materials or using heat and pressure methods. The products defining characteristic is that it uses only pressure and heat to extract the desired result and does not use chemicals or solvents at any point in the process.

How is Rick Simpson Oil (RSO) made?

Rick Simpson Oil (RSO) is a concentrated form of oil created by Dr. Rick Simpson. RSO is extracted by using a variety of solvents, primarily among those being naphtha or an alcohol-based solvent (Isopropyl). Hazekamp (2013) provides extensive research and lab-tested results on the various forms of cannabis oil extraction with the primary focus on naphtha, ethanol, and even olive oil extractions! RSO’s defining characteristic is that its starting material and final product both contain a vast majority of the plant’s natural compounds, waxes, lipids, flavonoids, and chlorophyll, many of which get filtered out, or completely degraded during other concentration extractions, or through natural exposure (L. Friesen 2020). In Cannabis Science and Technology, different chemical compounds gained and lost through the various extraction techniques performed today are listed and explained (2020). The full health benefits of marijuana are believed to be obtained if all of these elements are present. These elements react together with the terpenes and cannabinoids within the body. While studies today have neither confirmed nor denied the effectiveness of these chemical compounds and their synergy together within the body, RSO has gained a massive following. Although some natural plant elements are lost with the next form of concentrates and their extractions, they have the potential to produce the highest quality, taste, and effects of all products.

How is Full Extract Cannabis Oil (FECO) made?

Fully Extracted Cannabis Oil (FECO) is extracted by using a light hydrocarbon or ethanol to dissolve the desired extract from the marijuana flower. The starting material is integral to the final product. Nick Tennant, founder, and CTO of Precision Extraction explains various extraction methods on the company’s YouTube Channel. These videos explain the chemistry occurring in the background as well as how these products differentiate themselves throughout the process. As Nick describes in his video on concentrate extractions, anything distinguished with the “Live” characteristic (i.e. Live resin, Live budder, Live diamonds, Live sauze, etc.) is made using starting material harvested and frozen while technically “alive”. With this method, a product is created that closely mimics the original flavor profile and effects of the flower while also elevating them. Manufacturers can create diverse textures, consistencies, and concentrations for consumption by extracting cannabinoids and terpenes from a light hydrocarbon mixture and then evaporating the solvent. This gradient of settling can determine the final product that goes out to consumers depending on a manufacturer’s individual specifications (Growingtec 2020). Think about it like a gradient of lava as seen in Figure 4.20b (Pahoehoe Lava), where the hot liquid lava is terpenes/terp sauce products and the hard dried lava is cannabinoid/wax products.

How budder extract is made?

Growingtec’s Youtube channel has an in-depth video touring Cuban Crew Colorado’s extraction lab and together with the Lab Director Angel, providing an extremely easy-to-follow educational video describing the many different techniques applied to craft the perfectly desired product. As explained by both Angel and Nick (CTO of Precision Extraction Solutions), cannabinoids are heavier than terpenes and generally migrate to the bottom of an extract which then starts to clump together and crystallize as the solvent is either evaporated or purged out through a vacuum. Alternately, the terpenes will generally float to the top and create an oily liquid layer (Growingtech 2022 & Precision Extraction Solutions 2020). Oil can also be whipped post-extraction to increase the amount of oxygen bubbles added and create a whip-like texture. Dispensaries normally display this texture in the form of budders and glue chemical products.

What determines the consistency of shatter?

With dried (non-live) starting material, the process produces products free of plant fats, waxes, and lipids. This results in a more clear glass-like product known as shatter. As a result of natural degradation from drying and exposure, marijuana quickly loses those delicate terpenes. By extracting older products with hydrocarbons, we are able to produce a cannabinoid-dominant, terpene-recessive, and highly enjoyable product for consumers (Precision Extraction Solutions 2020). The rigidity of shatter is directly determined by the starting material’s state and genetics, as well as the method used for extraction. The presence of more cannabinoids results in hard, breakable shatter, whereas the presence of more terpenes results in soft, stretchy shatter.

How is cannabis distillate made?

What about distillate and isolate? The process is a bit more involved and requires a few refinement steps before distilling into the final product used in vapes, glass syringes, and cannabinoid crystals or powders (THCA Isolate, Diamonds, etc.). Luna Technologies goes into specific details in their blog: “Cannabis Distillate: Behind the Making of Pure & Potent Liquid Gold” on the extensive steps required to create these products. Isolate has been described as a distillate, since they are both purely cannabinoid extracts, and isolate is a purely crystallized distillate with no liquids, fats, or waxes (Luna Technologies 2022). The defining feature of this product is that it is generally a single cannabinoid extract refined and distilled to target a specific cannabinoid. This distillate refinement process is also responsible for ensuring product consistency so that it can be vaporized in electronic vape cartridges.

What concepts are needed to understand the big picture?

When a product is “live” as opposed to “normal,” the only difference is that the “live” starting material is immediately frozen and vacuum sealed after harvest to maintain peak terpene and cannabinoid levels. Rosin is a product that is sometimes also called “solventless” because the process used to extract the desired product only uses heat and applied pressure. Resin/budder/wax/terp sauce are all names for the same hydrocarbon extraction process and the differences in these products are the terpene and cannabinoid concentrations. In contrast, terpene sauces often contain only terpenes and no cannabinoids, whereas waxes and crumbles tend to be more cannabinoids-dominated. Budder products are generally the median in both terpenes and cannabinoids. They are made by whipping the oil extract to get a creamier budder/glue consistency by adding oxygen to the final product through the whipping technique. As an alcohol extraction, RSO can be distinguished by the fact that it contains a wide range of natural chemical compounds found in the original flower. This results in a synergistic effect that has been proven to be beneficial to health. The distillate is an alcohol extraction and is usually cannabinoid dominant, often only having one present throughout the final product. This is usually due to the distillation process, which heats sensitive terpenes out of the product. Isolate is the same as distillate, however, further refinement is done and removes many fats, lipids, and waxes as well as an activation step to convert THC. This results in a crystal-like structure of the target cannabinoid that is sold as an isolate (THCA Isolate) or as diamonds. Many more artisanal creations like suga products, diamonds, or caramel sauze seen in dispensaries are usually other blends of these base products in a creative combination.

With this knowledge, consumers can purchase a product that aids ailing individuals uniquely, as well as serving as a daily health supplement for general use. Atakan Z. (2012) says, “Cannabis is a complex plant with over 400 chemical entities of which more than 60 them are cannabinoid compounds.” Atakan continues into the complexity of the endocannabinoid system and how the receptors in the body and the various compounds present in marijuana interact. Regulation of this system is necessary not only to enhance the effectiveness of marijuana’s compounds in binding to and interacting with one another. However, dysregulation of this system can pose serious health risks. Tomko, et al. describe these systems in terms of dysregulation of the endocannabinoid system, which has been implicated in various diseases, including cancer. This dysregulation can include variation in the expression and/or function of cannabinoid receptors and enzymes, or simply alterations in the concentration of endocannabinoids,” (2020). Consumers rarely consider the health and regulatory aspects of this system when making decisions about which concentrate products to consume. With so many products in their various concentrations of flavonoids, natural plant compounds, terpenes, and cannabinoids, many consumers can find the perfect product that complements their unique biological system. The complexity and uniqueness expressed within consumer biological systems are matched with a complementary product that provides the intended health benefits. This is without the unintended side effects that may be present in other products. The synergy between these elements and their involvement within the body’s processes is constantly under study and with marijuana still being relatively new to acceptance into society, the jury is still out on any concrete long-term health benefits or deficiencies. It’s important to know: “What’s that concentrate and why should I smoke it?

Works Cited

Friesen, Exploring the Chemical Makeup of Cannabis Extract by Method Cannabis Science and Technology 3(6), 14-20 (2020) https://www.cannabissciencetech.com/view/exploring-the-chemical-makeup-of-cannabis-extract-by-method

O’Driscoll, A. L. A. (2022, September 27). A Guide to Drying and Curing Cannabis (L. A. Abernethy, Ed.). Analytical Cannabis. https://www.analyticalcannabis.com/articles/a-guide-to-drying-and-curing-cannabis-313091

Precision Extraction Solutions. (2020, February 17). Extraction Explained: How to Make Cannabis Extracts – Live Resin, Shatter, Craft Concentrates & More. YouTube. https://www.youtube.com/watch?v=n7cP6YWO_nc

Atakan Z. (2012). Cannabis, a complex plant: different compounds and different effects on individuals. Therapeutic advances in psychopharmacology, 2(6), 241–254. https://doi.org/10.1177/2045125312457586

Luna Technologies. Cannabis Distillate: Behind the Making of Pure & Potent Liquid Gold. Retrieved November 3, 2022, from https://blog.lunatechequipment.com/making-cannabis-distillate

Hazekamp, A. (2013, May 5). Cannabis Oil: Chemical Evaluation of an upcoming cannabis-based medicine. Cannabis Oil: chemical evaluation of an upcoming cannabis-based medicine. Retrieved October 30, 2022, from https://www.researchgate.net/profile/Arno-Hazekamp/publication/297707359_Cannabis_oil_Chemical_evaluation_of_an_upcoming_cannabis-_based_medicine/links/57c923a808ae9d6404818918/Cannabis-oil-Chemical-evaluation-of-an-upcoming-cannabis-based-medicine.pdf

Rosin Tech. (2020, October 30). The Art of Solventless — Rosin Tech Labs. YouTube. https://www.youtube.com/watch?v=vMBL2I8AsOo

Growingtec. (2022, April 8). How Cannabis Extracts are made [Start to Finish]. YouTube. https://www.youtube.com/watch?v=x8p6-CjKlps

Tomko, A. M., Whynot, E. G., Ellis, L. D., & Dupré, D. J. (2020). Anti-Cancer Potential of Cannabinoids, Terpenes, and Flavonoids Present in Cannabis. Cancers, 12(7), 1985. MDPI AG. Retrieved from http://dx.doi.org/10.3390/cancers12071985

Modern Canna

Modern Canna